Hydraulic Trailers

Ensure your hydraulic trailers stay in top condition with JTS Forklift Service. From 24/7 emergency repairs to preventive maintenance, our expert technicians provide reliable service for all makes and models across Utah, minimizing downtime and keeping your operations running smoothly.

Contact Our Team Today

Hydraulic Trailer Repair & Service (All Makes & Models)

In any industry that relies on heavy equipment, trailers are the unsung heroes of transportation and daily operations. When this crucial machinery is equipped with hydraulic systems, its capabilities expand, but so does the need for specialized care. A breakdown can halt progress, impact deadlines, and affect your bottom line. Understanding how to maintain and repair these assets is essential for business continuity.

This guide will explore the fundamentals of trailers that have hydraulics, common problems they face, and the importance of professional service. At JTS Forklift Service, our expertise extends beyond forklifts to include comprehensive maintenance and repair for all types of hydraulic equipment. We are committed to keeping your entire fleet running at peak performance.

Contact Us

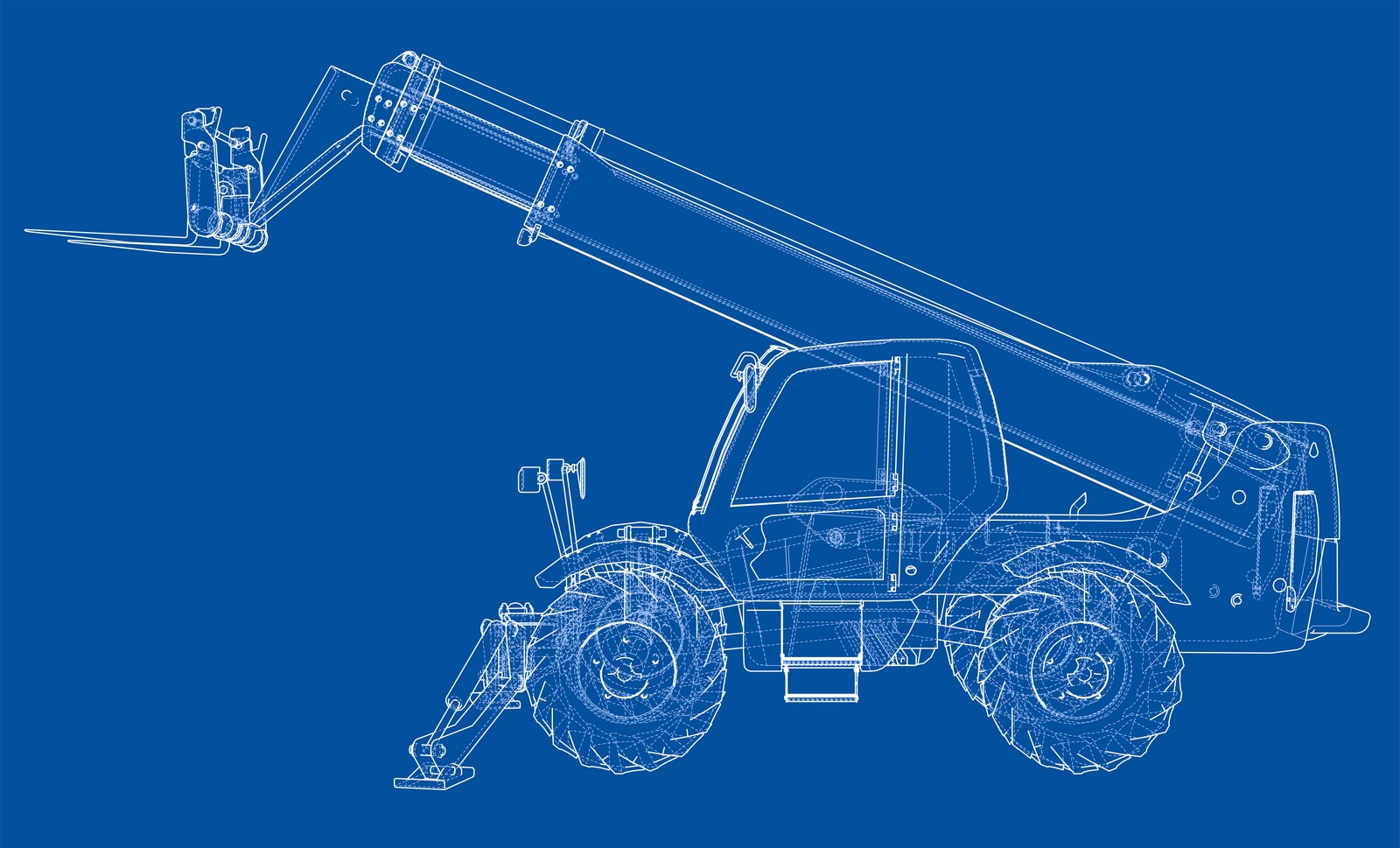

What Are Trailers That Have Hydraulics?

Trailers with hydraulic systems use pressurized fluid to power various functions, making them indispensable for lifting, tilting, and moving heavy loads. These systems are powerful and precise, but their complexity requires expert knowledge.

Key Components

A typical hydraulic system on a trailer includes several core parts working together:

- Hydraulic Pump: This is the heart of the system, creating the flow of hydraulic fluid.

- Cylinders: These actuators convert hydraulic pressure into linear motion to lift or tilt the trailer bed.

- Valves: These control the direction and flow rate of the fluid, directing the system’s actions.

- Hoses and Fittings: These conduits transport the fluid between components.

- Reservoir: This tank holds the hydraulic fluid, keeping it clean and cool.

How They Work

The pump pushes hydraulic fluid through hoses to the cylinders. By controlling the fluid’s path with valves, an operator can extend or retract the cylinders, enabling actions like dumping materials from a dump trailer or lowering a ramp on a utility trailer. Different models, such as car haulers, dump trailers, and equipment haulers, use these hydraulic systems to perform specific, powerful tasks that would otherwise be impossible.

Common Trailer Hydraulics Problems

Even with proper care, hydraulic systems can develop issues. Recognizing these problems early can prevent costly downtime and major repairs.

Common issues include:

- Hydraulic Fluid Leaks: Leaks are the most frequent problem. Worn seals, damaged hoses, or loose fittings often cause them. A leak reduces system pressure and can lead to equipment failure if not addressed.

- Slow or Weak Operation: If the trailer’s hydraulic functions are sluggish, it could be due to low fluid levels, a clogged filter, or a worn-out pump. Air in the system can also cause spongy, inefficient performance.

- Overheating: Excessive heat can damage hydraulic components and break down the fluid. Overheating may result from a low fluid level, a blocked cooler, or operating the equipment beyond its capacity.

- Unusual Noises: Whining or grinding sounds often indicate problems with the pump, usually due to aeration (air in the fluid) or cavitation (vapor bubbles forming and collapsing).

Attempting to fix these issues without proper training can lead to further damage or safety hazards. Working with a professional technician from JTS Forklift Service ensures that the problem is diagnosed correctly and repaired with the right tools and high-quality parts.

JTS Forklift Service's Expert Trailer Repair Solutions

At JTS Forklift Service, we offer a full range of services to keep your hydraulic trailers in optimal condition. Our skilled technicians have the expertise to handle all makes and models, providing reliable solutions to minimize your downtime.

Our services include:

- General Repairs: We diagnose and fix all hydraulic issues, from minor leaks to major component failures.

- Emergency Services: Equipment breakdowns don’t stick to a 9-to-5 schedule. That’s why we offer 24/7 mobile service across Utah to get you back up and running quickly.

- Preventive Maintenance: We provide fluid changes, system inspections, and performance testing to catch problems before they start.

Preventive Maintenance: Protecting Your Equipment

Proactive maintenance is the smartest way to safeguard your investment in equipment. By sticking to a consistent maintenance schedule, you not only extend the lifespan of your hydraulic systems but also reduce the likelihood of unexpected breakdowns and significantly cut long-term repair costs. Addressing potential issues early, such as replacing a worn hose or cleaning a dirty filter, can prevent minor problems from escalating into costly failures that cause downtime.

Why Preventive Maintenance Matters

Preventive maintenance also ensures that your equipment operates at its best, keeping productivity levels high and avoiding interruptions to your operations.

The key benefits of consistent maintenance include:

- Increased equipment reliability and uptime: Your machinery stays operational when you need it most, minimizing unplanned downtime.

- Enhanced safety for your operators: Properly maintained equipment reduces the risk of accidents and ensures a safer working environment.

- Lower overall operating costs: Catching and fixing issues early saves money on major repairs and replacements in the long run.

- Improved performance and efficiency: Well-maintained equipment runs more smoothly and efficiently, contributing to better productivity and performance outcomes.

Incorporating preventive maintenance into your routine is not just about protecting your equipment—it’s about optimizing your operations and ensuring long-term success.

Why Choose JTS Forklift Service?

When your operations depend on reliable equipment, you need a service partner you can trust to keep things running smoothly. JTS Forklift Service is your go-to solution for hydraulic trailer repairs and maintenance across Utah. Here’s why we’re the right choice:

- 24/7 Mobile Service: Equipment downtime can disrupt your entire operation, which is why we offer 24/7 mobile service. Our expert team will come to you, anytime and anywhere in Utah, providing on-site repairs to get you back up and running as quickly as possible.

- Expertise Across All Models: With over 30 years of combined experience, our technicians are skilled in servicing all makes and models of trailers, forklifts, and heavy equipment. No matter the brand or complexity, you can trust us to handle your equipment with precision and care.

- Quality and Speed: We understand the importance of durable repairs and minimizing downtime. That’s why we use only high-quality parts and work efficiently to ensure your machinery is back in service without unnecessary delays.

At JTS Forklift Service, we’re committed to providing reliable, expert care for your hydraulic systems and more. Discover our full range of services and see how we can help keep your operation running smoothly by visiting our services page.

Frequently Asked Questions

How often should I service my hydraulic trailer?

We recommend a full inspection at least once a year. However, trailers used heavily may require more frequent checks, such as every three to six months.

What are the signs of a failing hydraulic pump?

Common signs include unusual noises (whining or knocking), slower operation, and a noticeable decrease in lifting power.

Can I use any type of hydraulic fluid in my trailer?

No, it’s crucial to use the fluid recommended by the manufacturer. Using the wrong type can cause damage to seals and other components.

Is it safe to operate a trailer with a minor hydraulic leak?

Even a minor leak can become a major problem. It can lead to fluid contamination, loss of performance, and potential environmental hazards. We recommend repairing any leak as soon as possible.

JTS—Your Partner in Equipment Maintenance

Your hydraulic trailers are vital to your business, and keeping them in top condition is essential for productivity and safety. From routine preventive maintenance to emergency on-site repairs, a professional service provider ensures your equipment remains reliable.

Trust the experts at JTS Forklift Service to handle all your hydraulic service needs. Our commitment to quality, speed, and customer satisfaction makes us the ideal partner for your business. Contact us today for a consultation or to schedule a service.

We look forward to working with you!

Latest Blogs

Explore our past blog posts covering topics like forklift maintenance, electric forklifts, and more! We keep it fresh with insightful content to assist businesses in excelling in material handling operations.

Choosing the Right Electric Pallet Jack for Your Warehouse Needs

Modern warehouses rely heavily on efficient material handling equipment to maintain smooth operations. Among the most essential pieces of warehouse equipment, electric pallet jacks stand out as workhorses that can dramatically improve productivity while reducing...

Understanding the Hyster Forklift Maintenance Manual: What Operators Should Know

Your Hyster forklift maintenance manual serves as the foundation for keeping your material handling equipment running efficiently. However, navigating through technical specifications and maintenance schedules can feel overwhelming for many operators. Understanding...

Forklift Maintenance Log Best Practices: Stay Compliant and Organized

Proper documentation stands as the cornerstone of effective material handling equipment management. A comprehensive forklift maintenance log not only ensures compliance with safety regulations but also maximizes equipment performance and extends operational lifespan....

“Customer Satisfaction is Our Number One Priority.”

Julius A.