Efficient material handling is the backbone of countless Utah businesses, from bustling warehouses to small local companies relying on forklifts daily to maintain smooth operations. Forklifts are the unsung heroes of various industries, and understanding their anatomy is crucial for ensuring peak performance and safety. At JTS Forklift Service, we combine decades of expertise with a customer-centric approach to keep your forklifts—and your business—running flawlessly.

By exploring the key components of forklifts and the role regular maintenance plays, we aim to empower business owners, operators, and warehouse managers to make informed decisions about their equipment. This guide will also show how we at JTS Forklift Service are ready to support your operations with reliable, specialized services across Utah.

Why Forklifts Are Essential to Material Handling

Forklifts play a pivotal role in streamlining material handling operations and lifting and transporting heavy loads quickly and efficiently. Industries like logistics, retail, and manufacturing rely on this equipment for productivity and safety. Yet, without proper care, forklifts can quickly become liabilities. That’s why understanding their anatomy, functions, and maintenance requirements is paramount.

Meet JTS Forklift Service

When Utah businesses need dependable forklift repairs and maintenance, they turn to JTS Forklift Service, the state’s trusted name for quality care. What makes us different?

- Specialization in Electric Forklifts: Our expert technicians excel at maintaining energy-efficient, eco-friendly electric forklifts, which are a growing favorite among businesses.

- 24/7 Mobile Support: With around-the-clock services, we bring repairs and maintenance directly to your business, minimizing downtime and maximizing convenience.

- Customer-Centric Approach: We prioritize your operational success and offer tailored solutions to meet the unique needs of small and large businesses.

- All Makes and Models: Whether you’re working with propane-powered machines or cutting-edge electric equipment, our team has the expertise to handle it all.

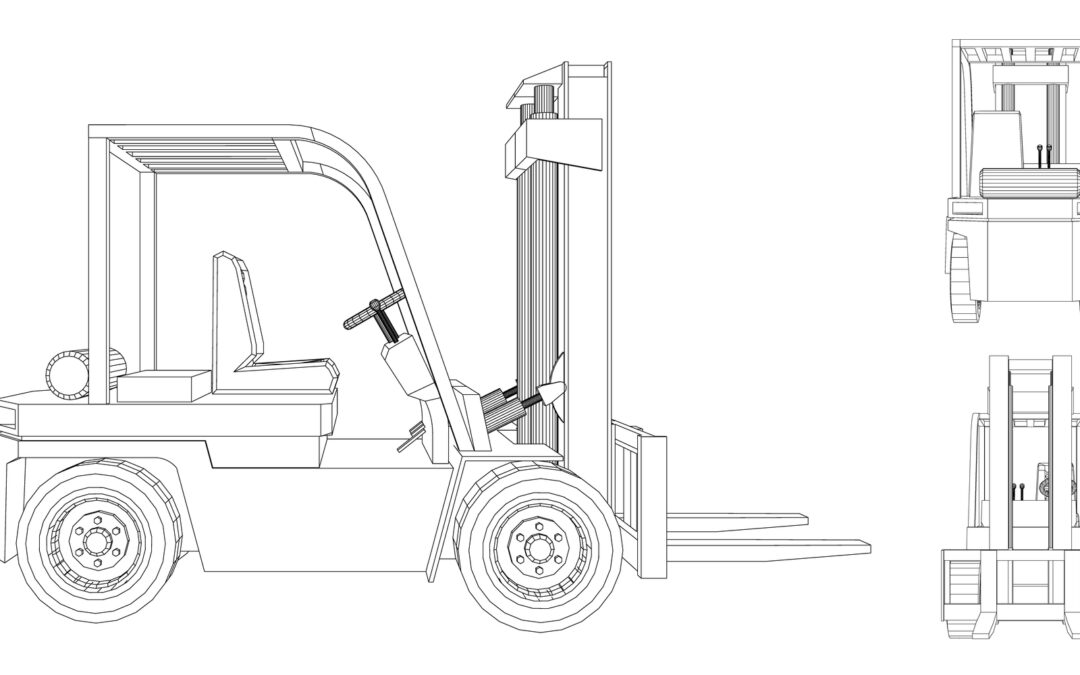

Forklift Anatomy 101

Understanding a forklift’s main components is essential for operators and maintenance teams. Here’s a closer look at some key parts and how they contribute to forklift functionality.

1. The Mast

The mast is the vertical assembly that raises and lowers the load. It works in tandem with hydraulic systems to lift pallets, crates, and other materials to varying heights. Common mast types include single, double, and triple-stage options, each catering to specific operational needs.

Importance of Maintenance

Regular mast inspections are crucial to ensure proper alignment and prevent any wear that could lead to operational delays or safety risks.

2. The Carriage

The carriage is the framework that moves along the mast, carrying the forks or other attachments that hold the load. Its design allows it to distribute weight evenly during lifts.

Maintenance Tip

Keep the carriage well-lubricated and inspect it for loose or damaged parts. Misaligned carriages can throw off balance and reduce the forklift’s performance.

3. Forks and Attachments

Forks are the extensions used to lift and hold loads. Additional attachments, such as clamps or push-pull mechanisms, enhance forklift versatility.

Key Insight

Bent or worn forks can compromise lifting capacity. Routine checks are vital to maintain safety and efficiency.

4. The Hydraulics

The hydraulic system powers the forklift’s lifting and tilting functions. It consists of pumps, cylinders, and fluid reservoirs, all working together to handle heavy loads securely.

Maintenance Essentials

Monitor hydraulic fluid levels regularly and replace any contaminated fluid to prevent malfunctions. At JTS Forklift Service, we offer comprehensive hydraulic fluid checks and changes to keep your machines running smoothly.

5. Power Source

Forklifts can be powered by internal combustion engines (using propane, diesel, or natural gas) or electric motors with rechargeable batteries. Electric forklifts are gaining popularity because they are eco-friendly and have lower operating costs.

Focus on Electric Forklifts

Battery health is a critical factor in electric forklift performance. Trust JTS for specialized battery maintenance, electric motor repairs, and charging system inspections.

6. Operator Cab and Controls

The cab houses the controls, including the steering wheel, brake, accelerator pedals, and levers for mast and fork operations. Ergonomics and visibility are key features that support operator performance.

Pro Tip

Ensure all controls are functioning correctly and that cab components are routinely cleaned to create a safe working environment for operators.

Why Maintenance Matters for Forklift Longevity

Neglecting regular maintenance can lead to costly breakdowns and safety concerns. Here’s why keeping up with maintenance is non-negotiable:

- Enhanced Longevity: Proper servicing extends the life of critical components, saving you from frequent replacements.

- Improved Safety: Faulty equipment increases the risk of workplace accidents. Regular safety checks reduce these hazards significantly.

- Optimized Performance: Regular tune-ups ensure forklifts operate efficiently, reducing fuel or battery waste.

At JTS Forklift Service, we offer comprehensive maintenance plans, from routine fluid changes to safety inspections. We’re dedicated to keeping your equipment in peak condition so your business can thrive.

JTS Forklift Service Keeps Utah Moving

Whether operating a single electric forklift in a small warehouse or managing a diversified fleet across a bustling industrial site, JTS Forklift Service has you covered. Here’s how we support your business:

- 24/7 Emergency Repairs: Equipment failures can throw a wrench in your plans. Our mobile service is available around the clock to get you back on track.

- Preventive Maintenance Plans: Scheduled servicing helps detect minor issues before they become significant problems.

- Parts Inventory: With access to a wide range of parts, we ensure swift replacements to minimize downtime.

- Electric Forklift Expertise: Our specialists are second to none in Utah, from battery maintenance to electric motor repairs.

Partner with JTS Forklift Service Today

Understanding the anatomy of a forklift is your first step toward efficient, safe operations. However, maintaining that efficiency requires a trusted partner who can deliver top-tier maintenance and repair services whenever you need them. That’s where JTS Forklift Service shines.

By partnering with us, you’re not just ensuring your forklifts operate at their best—you’re investing in the productivity and safety of your business.

Contact us today for a same-day service quote, and discover how we can keep your business moving forward.

GET IN TOUCH WITH US TODAY