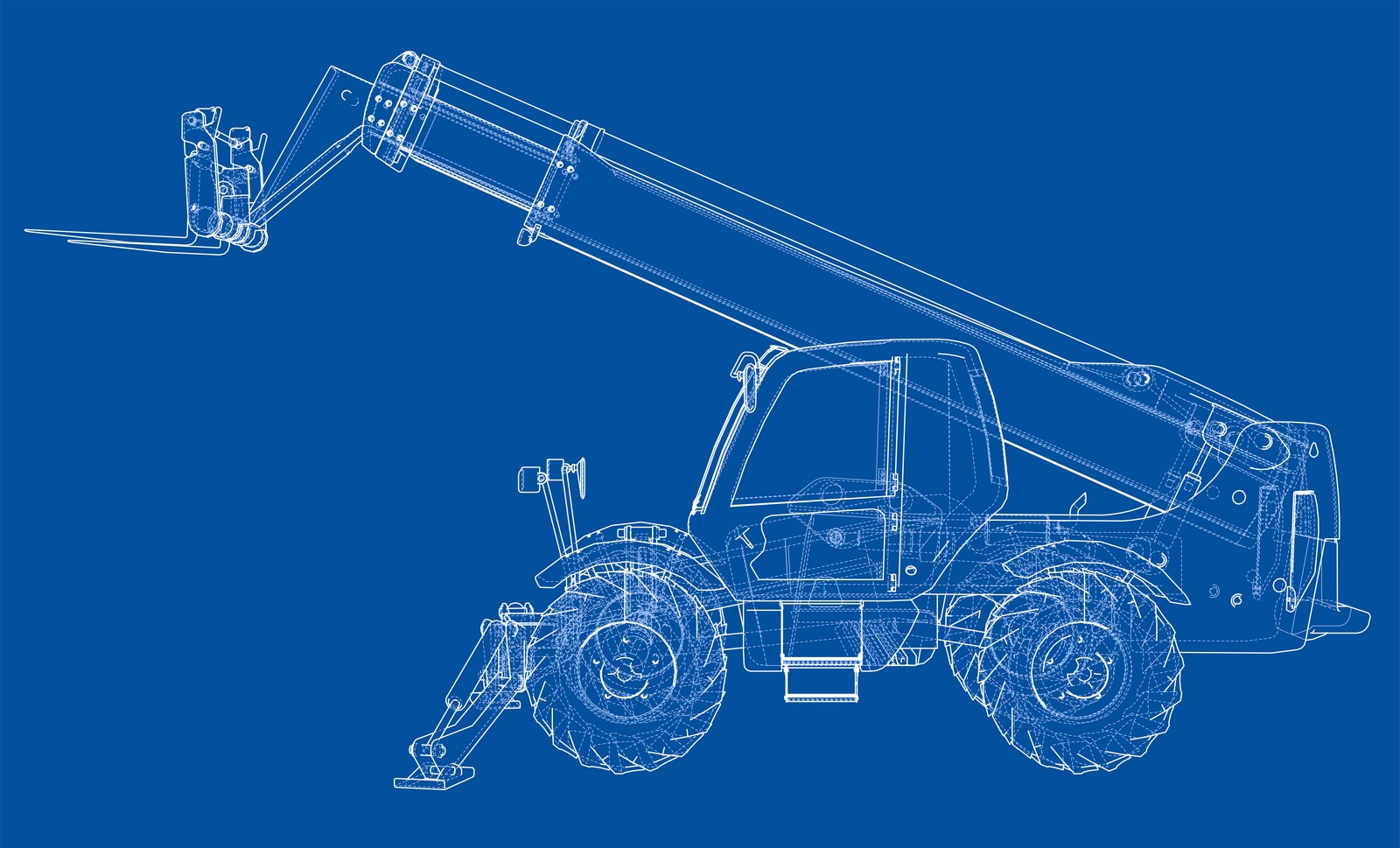

Cranes

Keep your cranes running safely and efficiently with expert maintenance and repair services from JTS Forklift Service. From hydraulic system repairs to 24/7 emergency support, we provide comprehensive care for all crane makes and models across Utah. Extend your equipment’s lifespan and prevent costly downtime with our professional solutions.

Contact Our Team Today

Crane Maintenance & Hydraulic System Repair

Cranes serve as the backbone of countless industrial operations, from construction sites to manufacturing facilities. These powerful machines handle massive loads daily, making proper maintenance and hydraulic system repair crucial for operational success. When your crane experiences downtime, productivity grinds to a halt—potentially costing thousands of dollars per hour.

Understanding crane maintenance requirements and hydraulic system complexities can mean the difference between smooth operations and costly breakdowns. Professional maintenance services ensure your equipment operates safely while extending its operational lifespan. At JTS Forklift Service, we recognize that proper crane care requires specialized expertise across all makes and models.

This comprehensive guide explores essential crane maintenance practices, common problems, and repair solutions. Whether you’re managing a single crane or an entire fleet, these insights will help you make informed decisions about your heavy equipment care.

Contact Us

Understanding Cranes: Key Components & Operations

Modern cranes rely heavily on hydraulic systems, which serve as the heart of their operations. These systems use pressurized fluid to generate an immense lifting force while maintaining precise control.

Key hydraulic components include:

- Pumps

- Cylinders

- Hoses

- Valves

- Filters

Each of these components plays a vital role in ensuring optimal performance and safety.

Structural Components: Boom, Mast, and Outriggers

The boom assembly is responsible for extending and retracting to reach various positions, while the mast provides crucial structural support during lifting operations. To ensure stability, outriggers distribute weight across a broader base, preventing tipping during use.

Electronic Control Systems and Safety Functions

Modern electronic control systems are integral to crane operations. They monitor performance parameters, manage safety functions, and provide operators with precise control, even during complex maneuvers.

The Importance of Regular Maintenance

Understanding how these components work together helps facility managers identify potential issues early. Regular inspections of hydraulic systems, structural elements, and control components can reveal wear patterns and maintenance needs, enabling proactive care strategies to avoid costly breakdowns.

Common Crane Problems and Professional Solutions

Heavy equipment operators often face specific crane issues that disrupt operations. Identifying these problems early can prevent costly repairs. Here are some of the most common issues and how professional solutions can help:

Hydraulic Fluid Leaks

Causes: Deteriorating seals, cracked hoses, or loose connections.

Impact: Reduced system pressure, compromised lifting capacity, safety hazards, and environmental concerns.

Boom Extension Problems

Causes: Worn cylinders or contaminated hydraulic fluid.

Impact: Jerky movements, slower extension speeds, or complete system failure due to cylinder scoring and seal damage.

Electrical System Malfunctions

Causes: Corroded connections, damaged wiring, or failed sensors.

Impact: Erratic crane behavior or total system shutdown, creating significant safety risks.

Professional Solutions

Systematic Diagnosis: Professional technicians identify root causes rather than addressing symptoms, ensuring durable repairs.

Specialized Tools and Genuine Parts: Experts use the right tools and parts to restore performance effectively, minimizing future breakdown risks.

Addressing these issues promptly and professionally ensures safer, more efficient crane operations.

JTS Forklift Service's Expert Crane Repair Solutions

JTS Forklift Service delivers crane maintenance and repair services throughout Utah. Our experienced technicians understand the critical role cranes play in your operations, providing swift solutions to minimize downtime.

General Repair Services for All Makes and Models

Our repair services cover all crane systems, from hydraulic components to electrical controls. We work with all makes and models, ensuring compatibility regardless of your equipment’s age or manufacturer. Plus, with our mobile service capability, we come directly to your location—reducing transportation costs and minimizing operational disruptions.

24/7 Emergency Repair Services

Crane failures don’t follow business hours, and neither do we. Our emergency repair services operate around the clock. When critical equipment fails, our rapid response team mobilizes immediately. With an extensive parts inventory and specialized tools, we aim to complete repairs on-site whenever possible.

Preventive Maintenance Programs

Preventive maintenance is the backbone of our approach. Our programs include:

- Regular fluid changes

- Comprehensive inspections

- Performance testing

These steps help identify potential issues before they lead to failures. We follow manufacturer specifications while incorporating industry best practices developed through decades of experience.

Preventive Maintenance: Protecting Your Equipment Investment

Proactive maintenance strategies deliver substantial benefits beyond simple breakdown prevention. Regular maintenance extends system life, reduces repair costs, and ensures consistent performance throughout your equipment’s operational lifetime.

Importance of Hydraulic Fluid Changes

Scheduled hydraulic fluid changes prevent contamination buildup that damages internal components. Fresh fluid maintains proper viscosity and lubrication properties, protecting pumps, cylinders, and valves from premature wear. Regular filter replacements remove contaminants before they cause system damage.

The Value of Comprehensive Inspections

Comprehensive inspections reveal wear patterns and potential failure points early in their development. Trained technicians examine hose conditions, check seal integrity, and test system pressures during routine visits. These inspections often uncover minor issues that can be addressed before they escalate into major problems.

Performance Testing for Safety and Efficiency

Performance testing validates system operation across all functions. Load testing ensures lifting capacity remains within specifications, while operational testing verifies smooth movement and precise control. Regular testing maintains safety standards while identifying declining performance trends.

Benefits of Maintenance Documentation

Documentation of all maintenance activities creates valuable service history records. These records help technicians identify recurring issues, track component replacement intervals, and plan future maintenance needs. Proper documentation also supports warranty claims and regulatory compliance requirements.

Why Choose JTS Forklift Service for Your Crane Needs?

JTS Forklift Service stands apart through our commitment to comprehensive heavy equipment care across Utah. Our 24/7 mobile service ensures prompt response regardless of location or time constraints. We understand that equipment failures don’t wait for convenient scheduling, so neither do we.

Expertise Across All Equipment Types

Our technicians have expertise with all equipment makes and models, from vintage cranes to the latest designs. This ensures effective service and quality repairs, no matter your equipment.

We prioritize high-quality parts and fast service. With strong supplier relationships, we source genuine components quickly. Our mobile units are equipped with tools and standard parts for on-the-spot repairs in most cases. Customer satisfaction is at the core of what we do. We know your success depends on reliable equipment, and we’re here to support your goals with services that meet immediate needs and boost long-term reliability.

For complete information about our crane maintenance and hydraulic system repair services, visit our services page to learn how we can support your operation.

Frequently Asked Questions

How often should crane hydraulic systems be serviced?

Hydraulic system service intervals depend on operating conditions and usage intensity. Generally, hydraulic fluid should be changed every 1,000-2,000 operating hours, with filters replaced more frequently. Heavy-duty applications may require more frequent service.

What are signs that my crane needs immediate repair?

Watch for unusual noises, jerky movements, fluid leaks, reduced lifting capacity, or warning light activation. Any of these symptoms warrants immediate professional inspection to prevent further damage or safety hazards.

Can preventive maintenance really reduce repair costs?

Yes, preventive maintenance typically reduces total repair costs by 25-40%. Regular maintenance identifies minor issues before they cause major component failures, resulting in lower parts costs and reduced downtime expenses.

Do you service all crane brands and models?

JTS Forklift Service has extensive experience with all major crane manufacturers and models. Our technicians regularly update their training to stay current with evolving technologies and manufacturer specifications.

Maximize Your Crane Performance with JTS

Effective crane maintenance and hydraulic system repair require specialized knowledge, proper tools, and genuine parts. Professional service providers deliver comprehensive solutions that extend equipment life while ensuring safe, reliable operation.

Regular maintenance schedules prevent costly breakdowns while maintaining peak performance levels. Professional technicians identify potential issues early, enabling cost-effective repairs before major failures occur. This proactive approach protects your equipment investment while ensuring consistent operational capability.

Ready to ensure your cranes operate at peak performance? Contact JTS Forklift Service today at (801) 300-2290 for expert maintenance and repair solutions. Our experienced team stands ready to provide the professional service your heavy equipment deserves, keeping your operations running smoothly and efficiently.

We look forward to working with you!

Latest Blogs

Explore our past blog posts covering topics like forklift maintenance, electric forklifts, and more! We keep it fresh with insightful content to assist businesses in excelling in material handling operations.

Arizona’s Hidden Costs of Forklift Downtime—And How to Avoid Them

In the blistering heat of an Arizona summer, the last thing any warehouse manager wants to hear is the silence of a stalled forklift. From the logistics hubs in Tolleson to the distribution centers in Tempe, forklifts are the heartbeat of industrial operations. When...

Forklift Maintenance Plans That Work: A Guide for Fleet Managers in Utah

For fleet managers in Utah, from the bustling distribution centers of Salt Lake City to the manufacturing hubs in Ogden, keeping material handling equipment operational is not just a goal but a daily necessity. A forklift down means a pallet stuck, a truck waiting,...

How to Choose a Forklift Maintenance Partner in Arizona’s Fast-Growing Industrial Corridor

In the sun-drenched industrial hubs of Phoenix, Mesa, and Glendale, the supply chain never really sleeps. From the logistics centers in Tolleson to the construction sites in Scottsdale, material handling equipment is the heartbeat of Arizona's economy. But as any...

“Customer Satisfaction is Our Number One Priority.”

Julius A.