Hydraulic Systems

Keep your heavy equipment running smoothly with JTS Forklift Service’s expert hydraulic system repairs and maintenance in Utah. From forklifts to excavators, our team ensures reliable performance with 24/7 mobile service and top-quality care.

Contact Our Team Today

Hydraulic System Repair & Maintenance for Heavy Equipment

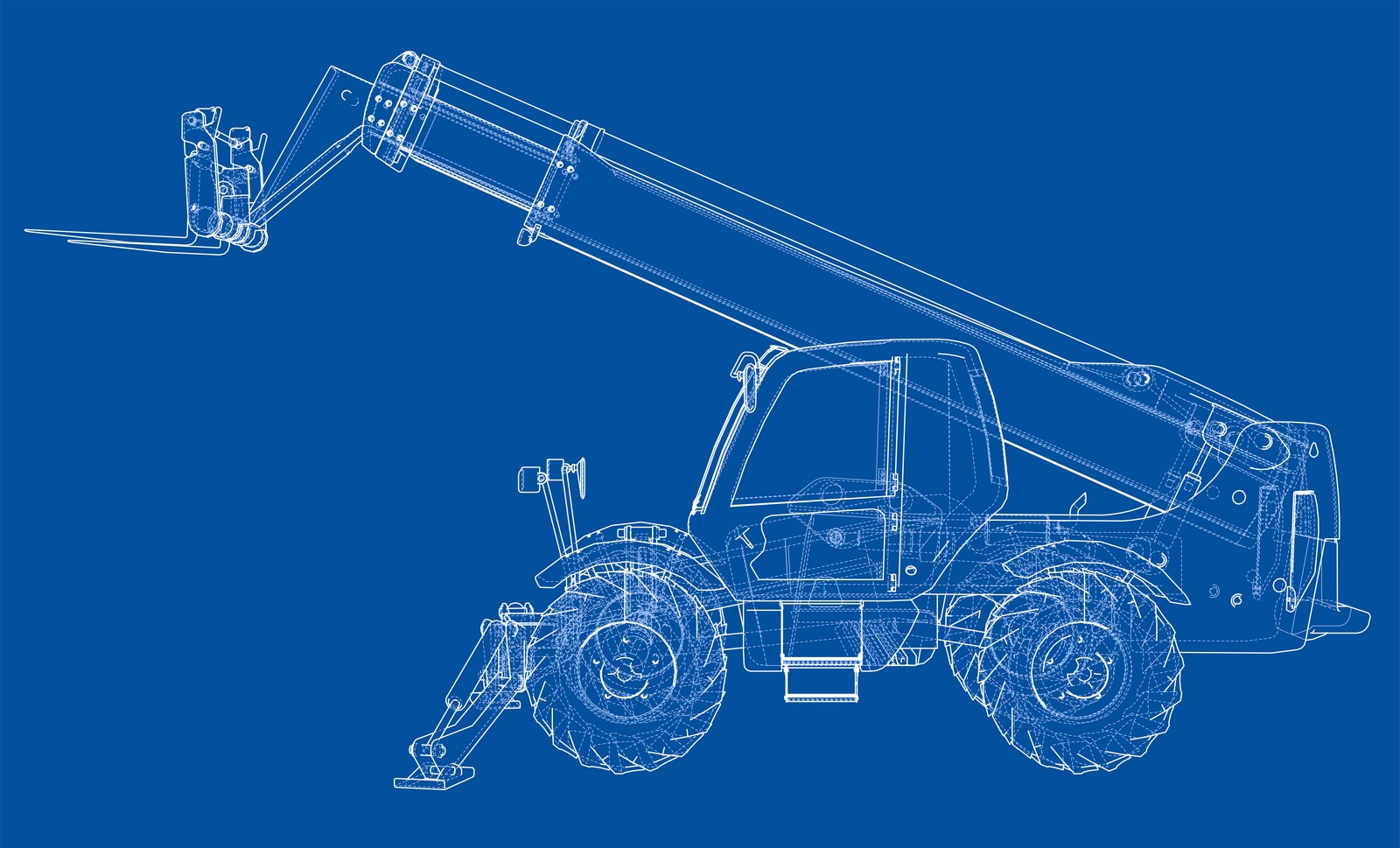

Hydraulic systems power the backbone of modern industrial operations. These sophisticated mechanical networks drive everything from forklifts and excavators to manufacturing equipment, making them essential for maintaining productivity across countless industries. When these critical systems fail, operations grind to a halt, costing businesses valuable time and revenue.

At JTS Forklift Service, we understand the critical role hydraulic systems play in your daily operations. Our experienced technicians specialize in comprehensive equipment repairs and maintenance services for heavy machinery throughout Utah. Our technicians service a wide range of hydraulic-powered equipment, including forklifts, excavators, skid steers, and other heavy machinery used in construction, agriculture, and industrial settings. With over 30 years of combined expertise in material handling equipment, we deliver the reliable solutions your business needs to stay operational.

Whether you’re dealing with a sudden system failure or planning preventive maintenance, our team stands ready to provide expert service that keeps your equipment running at peak performance. We work on all makes and models, ensuring your equipment receives the specialized care it deserves.

Contact Us

Understanding Hydraulic Systems in Heavy Equipment

Hydraulic systems operate on Pascal’s principle, using pressurized fluid to generate tremendous force through a network of interconnected components. These systems consist of several key elements working together seamlessly.

The Role of the Hydraulic Pumps and Fluid

The pump serves as the system’s heart, pressurizing fluid and circulating it throughout the network. This pump draws fluid from the reservoir and sends it under pressure through a series of hoses and valves to various actuators.

Hydraulic fluid itself plays a crucial role beyond simply transmitting power. This specialized fluid:

- Lubricates moving components

- Transfers heat away from critical areas

- Maintains consistent pressure throughout the system

Different equipment types require specific hydraulic fluid formulations to ensure optimal performance and longevity.

Cylinders and Motors: Converting Fluid Energy

Cylinders and motors convert the pressurized fluid’s energy into mechanical motion. Hydraulic cylinders provide linear motion for lifting, lowering, and extending operations, while motors generate rotational force for driving wheels or rotating equipment.

Control Valves and Filters

Control valves regulate fluid flow and pressure throughout the system. These components:

- Direct fluid to specific actuators

- Control operation speed

- Maintain system pressure within safe operating parameters

Filters keep fluids clean, preventing contamination that could damage sensitive components.

Identifying Common Hydraulic System Problems

Recognizing hydraulic issues early prevents minor problems from becoming costly repairs. Several warning signs indicate your system needs attention.

- Slow or Erratic Operation: Slow or inconsistent equipment response may signal declining hydraulic performance. Internal leakage or contaminated fluid could be reducing system efficiency.

- Unusual Noises: Grinding, squealing, or excessive noise from the hydraulic pump often indicates worn components or contaminated fluid. These noises should never be ignored, as they may lead to complete system failure.

- Fluid Leaks: External leaks create safety hazards and reduce efficiency, while internal leaks can cause erratic operation or reduced lifting capacity.

- Overheating: Excessive heat from working beyond system design indicates issues like contaminated fluid, worn components, or inadequate cooling, all of which can accelerate wear and damage.

- Contaminated Fluid: Contaminated fluid appears dark, cloudy, or contains visible particles. Clean fluid should be clear and consistent in color. Regular fluid analysis is essential for system longevity.

JTS Forklift Service's Expert Hydraulic Repair Solutions

Our comprehensive heavy machinery repair services address every aspect of your equipment’s hydraulic systems. We begin each service call with thorough diagnostics to identify the root cause of system issues rather than simply treating the obvious symptoms.

Our experienced technicians use advanced diagnostic equipment to test system pressure, flow rates, and component performance. This systematic approach ensures we identify all issues affecting your hydraulic system’s operation, preventing recurring problems and unexpected failures.

Hydraulic Pump and Cylinder Repair Services

Hydraulic pump repair and replacement represent a core competency for our team. We service all major pump types, including:

- Gear pumps

- Vane pumps

- Piston pumps

Our technicians understand the unique characteristics of each pump design, ensuring proper repair techniques and component selection.

Our cylinder repair services include:

- Seal replacement

- Rod reconditioning

- Complete cylinder rebuilds when necessary

We stock high-quality seals and components to enable immediate repairs, minimizing downtime for your operations.

Valve and Hydraulic Hose Services

Valve service encompasses cleaning, rebuilding, and calibration of control valves, relief valves, and directional valves. Proper valve operation is critical for safe, efficient hydraulic system performance, making this service essential for reliable equipment operation.

Our hydraulic hose services include custom hose fabrication, installation, and emergency repairs. We maintain an extensive inventory of hoses and fittings, enabling quick repairs to get your equipment back to work promptly.

Preventive Maintenance: Protecting Your Equipment

Proactive maintenance significantly extends system life while reducing unexpected repair costs. Regular maintenance prevents minor issues from developing into major failures that can sideline your equipment for extended periods.

The Importance of Hydraulic Fluid Changes

Scheduled fluid changes remove contamination and maintain optimal fluid properties. Fresh hydraulic fluid provides:

- Better lubrication

- Improved heat transfer

- Consistent performance throughout your system’s operating range

Keep Fluids Clean with Filter Replacement

Filter replacement services ensure your hydraulic fluid remains clean and free from harmful contaminants. We recommend filter changes based on:

- Operating hours

- Fluid analysis results

This approach customizes maintenance schedules to match your equipment’s specific operating conditions.

Inspections to Prevent Equipment Failure

System inspections are designed to identify potential problems before they lead to equipment failure. Our technicians carefully examine hoses, fittings, seals, and components to detect any signs of wear or damage. By addressing these issues early, timely repairs can help prevent costly breakdowns and keep your equipment running smoothly.

Gain Insights with Fluid Analysis Testing

Fluid analysis testing offers valuable insights into the internal condition of your hydraulic system. By conducting regular testing, you can identify contamination levels, additive depletion, and signs of component wear. These findings enable us to recommend the right maintenance actions to address issues before they develop into bigger problems.

Optimize Performance with Pressure Testing

Pressure testing verifies proper system operation and identifies components that may be operating outside design parameters. This process helps:

- Optimize system performance

- Identify components that require attention

Why Choose JTS Forklift Service?

At JTS Forklift Service, our unwavering commitment to excellence has made us Utah’s leading hydraulic service provider. With a blend of deep technical expertise and a genuine focus on customer satisfaction, we ensure your equipment gets the exceptional care it deserves. Customer satisfaction is at the heart of everything we do, driving our mission to build lasting partnerships with businesses across Utah. By delivering consistent, reliable service, we help support your operations and contribute to your long-term success.

24/7 Mobile Service

Available 24/7 throughout Utah, our mobile service team responds quickly to hydraulic emergencies. We understand that equipment downtime costs money, so we prioritize rapid response times that get your operations running again.

Expertise Across All Equipment Makes and Models

Our technicians possess comprehensive knowledge of hydraulic systems across all equipment makes and models. This broad expertise enables us to service diverse equipment types, from electric forklifts to backhoes, loaders, and beyond.

Quick Repairs with Quality Parts

- Extensive parts inventory for immediate repairs

- High-quality components to ensure durability

- Prompt service to minimize downtime and keep your operations productive and profitable

Optimize Your Business with JTS

Hydraulic systems represent sophisticated technology that requires specialized knowledge and proper maintenance to deliver reliable performance. When problems arise, prompt professional service prevents minor issues from becoming major expenses.

At JTS Forklift Service, we stand ready to support your hydraulic system needs with comprehensive repair and maintenance services. Our experienced team combines technical expertise with genuine commitment to customer satisfaction, ensuring your equipment receives the quality care it deserves.

Don’t let hydraulic problems disrupt your operations. Contact JTS Forklift Service today at (801) 300-2290 for expert hydraulic system service throughout Utah. Our mobile service team is available 24/7 to provide prompt, professional solutions that keep your business moving forward.

We look forward to working with you!

Latest Blogs

Explore our past blog posts covering topics like forklift maintenance, electric forklifts, and more! We keep it fresh with insightful content to assist businesses in excelling in material handling operations.

Understanding the Hyster Forklift Maintenance Manual: What Operators Should Know

Your Hyster forklift maintenance manual serves as the foundation for keeping your material handling equipment running efficiently. However, navigating through technical specifications and maintenance schedules can feel overwhelming for many operators. Understanding...

Forklift Maintenance Log Best Practices: Stay Compliant and Organized

Proper documentation stands as the cornerstone of effective material handling equipment management. A comprehensive forklift maintenance log not only ensures compliance with safety regulations but also maximizes equipment performance and extends operational lifespan....

Forklift Battery Maintenance Checklist: How to Avoid Downtime and Damage

Proper forklift battery maintenance can mean the difference between smooth operations and costly downtime. At JTS Forklift Service, we've seen firsthand how a structured maintenance approach prevents expensive repairs and keeps Utah businesses running efficiently....

“Customer Satisfaction is Our Number One Priority.”

Julius A.